Product Description

Rolled lead-calcium-tin and lead antimony alloys are the preferred anode materials in these applications, because of their high resistance to corrosion in the sulfuric acid used in electrolytic solutions. Lead anodes also have high resistance to corrosion by seawater, making them economical to use in systems for the cathodic protection of ships and offshore rigs.

Rolled lead anodes have become the industry benchmark with the benefits of fine grain structure, less segregation and elimination of cracks and voids resulting in more uniform corrosion of the anode.

High Efficiency & PurityWith a purity rate exceeding 99.99%, our lead anodes ensure exceptionally high current efficiency-reaching up to 95%. This translates to optimal performance in electrowinning, electroplating, and metal refining processes, delivering consistent results with minimal contamination or waste.

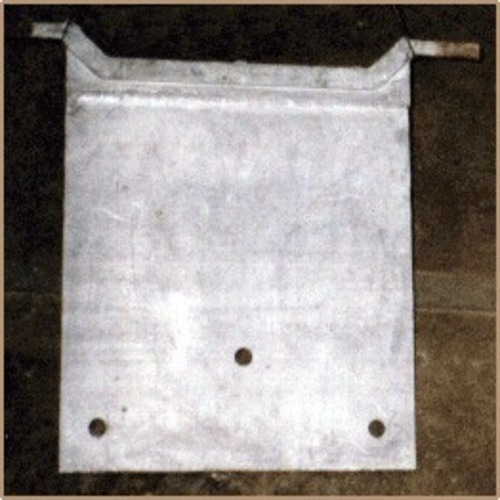

Customizable for Diverse ApplicationsWe offer full customization on anode dimensions, alloy composition, and connection types (stud, hook, bar) to meet specific project needs. Whether you require flat or rectangular shapes, various thicknesses, or unique alloy blends with silver or antimony, our anodes are built to specification for seamless integration.

Durable & Acid Resistant DesignEngineered for harsh industrial environments, our lead anodes feature a smooth, acid-resistant surface. Crafted using advanced pressure molding and casting, they provide excellent corrosion resistance and stability, ensuring a service lifespan of 2-3 years even under demanding conditions.

FAQ's of Lead Anode for Electrowinding:

Q: How are your lead anodes manufactured to ensure quality and durability?

A: Our lead anodes are produced using advanced pressure molding and casting processes with 99.99% pure lead, optionally alloyed with minimal amounts of silver or antimony. This method combines structural integrity with high acid and corrosion resistance to ensure a long-lasting product.

Q: What types of industries commonly use these lead anodes?

A: Our lead anodes are extensively used in industries involved in electrowinning, electroplating, and metal refining. They are ideal for operations that demand high current efficiency, excellent surface finish, and chemical stability.

Q: Can the lead anodes be customized for specific installation requirements?

A: Yes, we offer complete customization for dimensions (length, width, height), thickness, alloy composition, and connection type (stud, hook, or bar). This ensures compatibility with various horizontal or vertical mounting setups and unique project specifications.

Q: What are the main benefits of using high purity and acid-resistant lead anodes?

A: High purity guarantees superior current efficiency-up to 95%-while the acid-resistant nature provides prolonged operational life and maintains surface integrity, even in aggressive electrolytic environments. This results in higher productivity and reduced maintenance frequency.

Q: Where can your lead anodes be sourced and in what quantities?

A: As a manufacturer, supplier, distributor, and exporter based in India, we supply lead anodes nationwide and for export. Quantities can be tailored to individual project requirements, with standard and custom options readily available.

Q: What is the recommended operating temperature and lifespan of the lead anodes?

A: Our lead anodes are designed to operate efficiently at temperatures up to 60C, with a typical service lifespan ranging from 2 to 3 years under standard use and proper maintenance conditions.