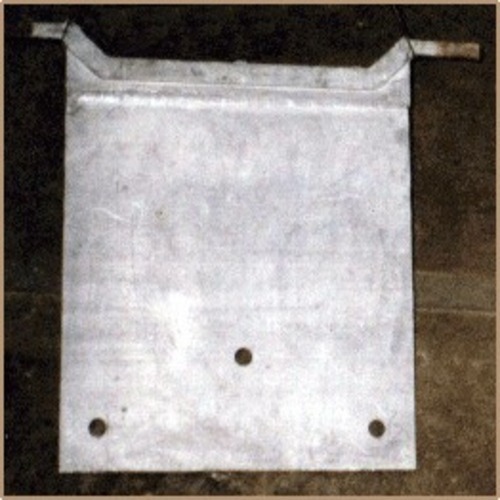

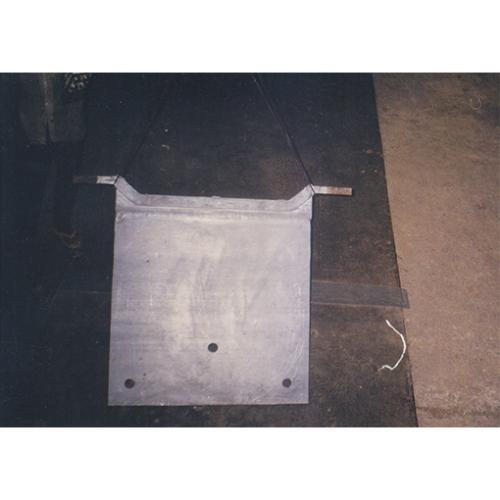

Product Description

used in copper, zinc and nickel refining. Our electrowinning anodes integrate years of experience, research and development.

With fully Integrated & 100% in-house production facility we are able to Internally controlled workmanship for alloying, rolling blade, head bar tinning and casting, welding, cutting & packaging.

Although anodes are manufactured to clients designs, with each stage of manufacture using the best quality raw materials and controlled by a strict quality process system, anodes are produced efficiently and consistently within estimated time.

Rolled lead-calcium-tin and lead antimony alloys are the preferred anode materials in these applications, because of their high resistance to corrosion in the sulfuric acid used in electrolytic solutions. Lead anodes also have high resistance to corrosion by seawater, making them economical to use in systems for the cathodic protection of ships and offshore rigs.

Rolled lead anodes have become the industry benchmark with the benefits of fine grain structure, less segregation and elimination of cracks and voids resulting in more uniform corrosion of the anode.